Barcode Inspection

Vehicle production is growing. Each automobile requires hundreds of components, making vehicle assembly an intricate dance of ensuring the right component is available at the right time in the right place.

Barcodes are ubiquitous for their ability to transfer tremendous amounts of data rapidly using nothing more than ink on paper. For a low cost, high speed way to transfer thousands of bytes of data, barcodes remain the technology of choice.

We are introducing new product innovations and upgrades to support your increased business requirements for barcode inspection, plus RFID media handling and encodings.

Our team was excited to join the RFID Journal LIVE! 2022 event in person, the world’s largest exhibition and conference for RFID and IoT products and services, which took place May 17-19 at the Mandalay Bay in Las Vegas.

All it takes to create a major supply chain and production issue is not having the right part, at the right location, at the right time. For example, a shortage of computer chips impacts the number of cars being made.

In the TEKLYNX blog post, “Better Connections For More Secure Barcode Labeling,” TEKLYNX Operations and IT Manager, Anthony Bienie

Supply chain optimization used to be focused on lean inventory management strategies and leveraging interconnected networks.

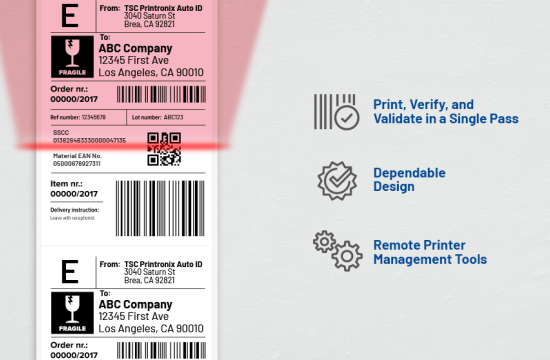

At TSC Printronix Auto ID, we have a versatile lineup of mission-critical printers that comprise our enterprise line.

Finding the right printer for your business needs can sometimes feel overwhelming. During your search, you may ask yourself questions like: Will it have all the right functions to ensure high quality labels? Can it do everything efficiently and accurately?