Why Integrated Barcode Verifiers are the Most Accurate and Efficient Method

Barcodes drive commerce and keep the global supply chain moving forward. Unreadable barcodes can halt production, result in fines, or prevent a pallet from arriving at its destination. This is why it’s critical for suppliers to verify and validate every barcode label for every package.

Barcode Verification and Manual Inspection Challenges

Barcodes move products worldwide. But before you ship, how do you know whether your barcode is readable across the supply chain? That’s where barcode verification and validation come in. A barcode verifier will check the quality of your barcode label. It starts by scanning your barcode and providing an “A” through “F” letter rating based on several factors:

- Module or bar size

- Contrast

- Reflectents

- Defects

Additionally, barcode verifiers use a specific lighting setup and calibration process that follows strict ISO guidelines to ensure that defects are caught before they become a problem using a repeatable process.

Barcode verification helps avoid costly product returns, package waste, printing errors, and keeps the supply chain moving forward efficiently.

Unfortunately, manual spot checks are not as efficient and do not check every barcode. This method requires adding a scanner, a PC as the controller, and someone to perform the test. If the label error rate is low, the chances of catching a bad barcode with a spot check are next to zero. If it is caught, your entire process must come to a halt to ensure the barcode is reprinted and placed on the correct shipment, all of which requires manual intervention.

That’s a lot of added time, space, and expense for very little, if any, reward.

Boost Efficiency with Integrated and Automated Barcode Verification

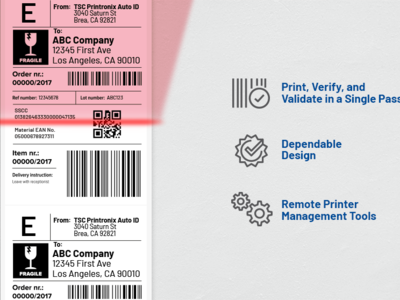

With our integrated barcode inspection printers, you can rest assured that your label printing process has a safeguard in place to avoid costly errors. Our ODV-2D printers come equipped with our unique integrated barcode inspection system to automatically verify and validate every single barcode label printed. Better yet, because the barcode verifier is integrated into the printer’s footprint, it does not require additional equipment, PCs, software, or operator intervention.

If an unacceptable barcode is found, the label is automatically retracted, overstruck, and a new one is printed. This saves time, money, and ensures your business continues to run at full capacity. It also ensures you’re delivering easy-to-read barcode labels to your downstream customers, eliminating any holdups to their processing that could lead to a fine for you. This frees up time so you can focus on what you’re good at—your business!

We have two printers with the integrated barcode verification and validation system, the T6000e and T8000 enterprise-grade ODV-2D printers.

T6000e Series 4-Inch Enterprise Industrial ODV-2D Barcode Inspection Printers

The award-winning T6000e Enterprise Industrial Printer offers top-of-the-line ODV-2D barcode verification technology to overstrike and correctly reprint 1D and 2D barcodes that were not printed clearly across multiple resolutions. It is the first printer system to grade barcodes to ISO 15415,15416 and 15426 standards and store a detailed report of each transaction. Our exclusive technology reads each barcode, identifies a rejected barcode, and reprints a replacement label automatically without operator intervention. Plus, it is equipped with RFID capabilities that set it apart from other printers.

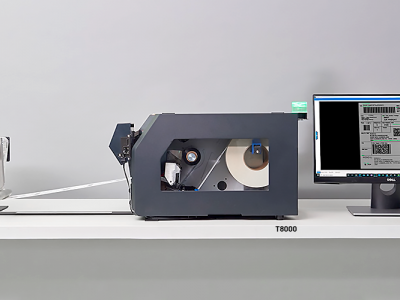

T8000 Series 4-Inch or 6-Inch Enterprise Industrial ODV-2D Barcode Inspection Printers

Our most robust printer with 4-inch or 6-inch print width, the T8000 Enterprise Industrial Printers feature a color display and multi-connectivity capabilities with optional ODV-2D inline barcode verifier technology. Our ODV-2D inspection system is the industry’s first affordable, fully integrated solution with the ability to print, verify, and validate 1D and 2D barcodes during the printing process. Built on the robust T8000 printer platform, these printers include a built-in data validator that grades barcodes to ISO standards and stores a detailed report of each transaction.

To learn more about the T6000e and T8000 Enterprise Industrial ODV-2D Printers for barcode verification and validation, contact your local TSC Printronix Auto ID sales representative or visit our website.