How Barcodes Power Just-in-Time Manufacturing for Automotive

Understanding inventory location is the key to a strong supply chain and Just-in-Time (JIT) manufacturing execution.

In this next edition of our TSC Auto ID Blog Series “Rev Up Savings,” we tackle Just In Time manufacturing for the automotive industry.

The right parts, at the right time, at the right location. This drives the modern supply chain, and it is all powered by those black and white patterns thermally printed on the self-adhesive labels. Yes, we’re talking about barcodes, those simple little patterns that with massive, global power. Now, let’s explain how reliable barcodes drive an optimized JIT approach. Learn precisely how critical data is derived from barcodes, and how it drives your supply chain.

JIT’s Unsung Hero: Barcodes & How They Really Work

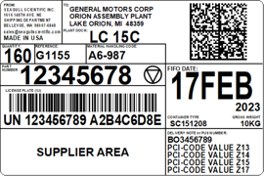

Barcode readers interpret black and white bars (1D symbologies) or boxes (2D) symbologies to encode characters in much the same way computers use 0’s and 1’s to encode your “Candy Crush” and “Angry Birds” games. This data is often used for much more mundane tasks like identifying part codes, providing batch and lot information for traceability, syncing products to manufacturers, and providing logistics data for shippers, carriers, and receivers. The fact remains that barcodes drive our economy. Every day over 10 billion GTINs are scanned (GS1). These Global Trade Item Numbers (GTIN) include UPCs and other part identifiers and make up only one subset of the total number of printed and scanned codes. Automotive industrial groups like AIAG (Automotive Industry Action Group), VDA (Verband der Automobilindustrie), and Odette have issued label specifications and standards to support the complex automotive supply chain to reduce mistakes and limit the severity of the supply chain disruptions. The various label formats used throughout the automotive industry can contain up to 10 barcodes per label with multiple symbologies including Code39 and 2D codes like PDF417 and the Datamatrix example in Figure 1.

Figure 1. GM template 1724-A for container shipping labels facilitating global trade in GM’s supply chain.

Relying on barcodes for just-in-time manufacturing has been a boon to streamline complex supply chain movements, but they’re not without challenges. So then, what happens when these critical labels fail? Poor print quality can cause havoc with missing items, parts that go missing, or even the wrong components or kits getting delivered to value streams all that reverse the advantages from JIT processes. But there’s help around the corner.

In just the last year, TSC Auto ID has helped dozens of Tier 1 and Tier 2 automotive suppliers with their barcode print quality issues. As an example, a major manufacturer that provides key safety equipment for automobiles turned to us to guarantee these critical car components made it to the right assembler, just-in-time. They provide seat-belts, airbags, inflators, and key electronics that keep us safe every day. They’ve been a long-time user of our enterprise T8000 series printers, but with the increasing adoption of 2D barcode symbologies, upgrading to the ODV-2D verification module was to quote them, “a no-brainer.” With return on investments (ROI) calculated in months or even weeks, these small investments to guarantee print quality have resulted in less disruptions, less chargebacks, and higher customer satisfaction. So next time you buckle-up, consider the efficient, accurate, and timely journey that belt assembly took from manufacturer to assembler all powered by high quality barcodes.

Barcode Verification Solution

The ODV-2D from TSC Auto ID offers automated and worry-free barcode verification and label inspection to your value stream and is a natural upgrade for your existing label printing operation. Want to see the ODV-2D in action? Watch here.

Learn More

Want to dive deeper? Find out how other manufacturers in the automotive market are using online data verification to solve unscannable barcodes -- to reduce errors, save money, and maximize productivity and equipment uptime. The TSC Auto ID Automotive Solutions page features comprehensive information including blogs, videos, graphs and more

We’ll continue to show you how in-depth, over the coming weeks, in this comprehensive Blog series ‘Rev Up Your Savings.’

Contact Us

Click here to schedule a consultation.