Global Game-Changer: Rise of 2D Codes

If you are in the AIDC industry or work with barcodes regularly, you need to be aware of the rising importance and usage of 2D codes like QR Code®, Data Matrix and a few other matrix codes.

Of particular importance are the initiative from GS1 called “Sunrise 2027” and pending traceability requirements such as FSMA 204, DSCSA and Europe’s Digital Product Passport (DPP). These initiatives and regulations can only be fulfilled with item-level identification, the kind of which 2D Codes now offer.

Why are 2D codes important?

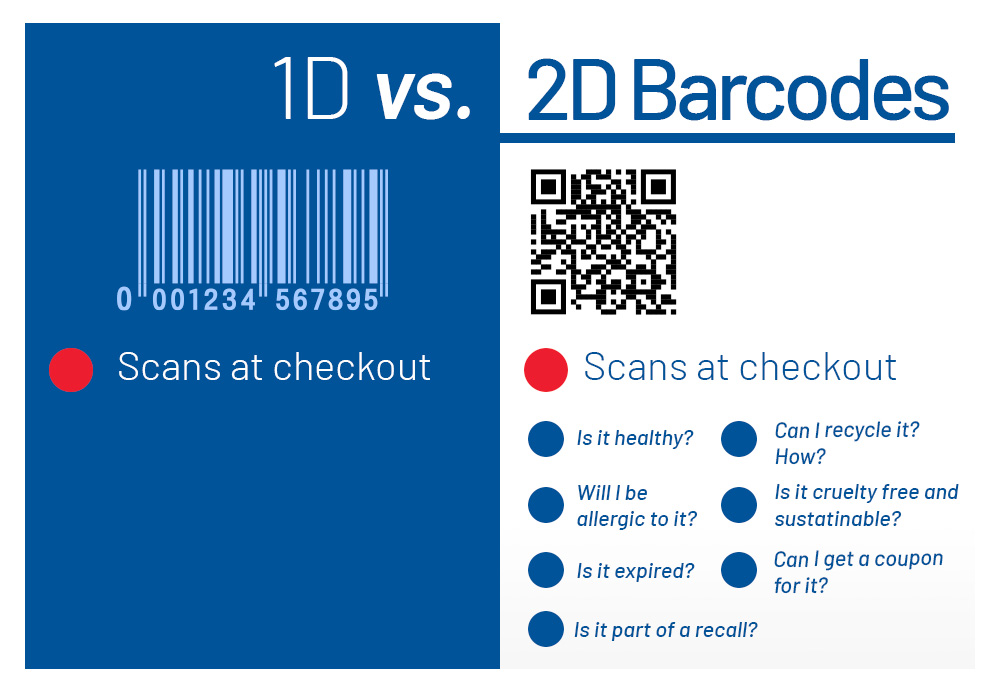

2D codes allow for more data in less space than traditional linear barcodes. The amount of extra data that can be encoded in a 2D code carries users across a sort of “critical threshold.” That threshold is the capability to assign unique identifiers and associated real-time attributes to each item. This is generally not practical with linear barcodes due to space constraints (some linear barcodes even have technical limitations on the number of characters that can be encoded). With 2D codes, one pair of jeans can be uniquely identified, traced and distinguished from other pairs of similar jeans. A 2D code on a pharmaceutical item could contain additional real-time information beyond the serial number such as an expiration date right in the code for automated identification and processing. The possibilities and implications of item-level identification are endless.

Key Types of 2D Codes

QR Codes®: Versatility at Your Fingertips

The ubiquitous QR Code® has become a staple in everyday life. Its ability to store substantial data makes it incredibly versatile. From directing consumers to product information and website links to streamlining supply chain tracking and facilitating mobile payments, QR Codes are revolutionizing how we interact with information.

DIVE DEEPER: Read more about TSC’s innovative use of QR Codes in the Automotive industry.

Data Matrix and GS1 DataMatrix: Precision and Traceability for Critical Industries

For industries demanding stringent traceability and data integrity, Data Matrix codes are the preferred choice. Their compact size and robust error correction capabilities make them ideal for marking small components in aerospace, pharmaceuticals, and electronics. Data Matrix codes play a crucial role in preventing counterfeiting and ensuring product authenticity throughout the supply chain.

What is the global compatibility impact?

On the scanning side of the equation, the rise of 2D codes means that the millions of installed scanners need to be checked for compatibility with 2D codes. And if a scanner at, for example, a retail checkout cannot properly decode a retail 2D code, then that scanner will need to be updated or even replaced completely. GS1 and the University of Memphis have been diligently testing scanners with 2D codes for several years to provide clear guidelines for all.

On the other side of the equation, the side where the 2D codes will be generated, software systems will need to be updated to accommodate item-level data as opposed to the traditional SKU-level data. Additionally, thousands of printing systems, including those employing thermal label printers from TSC, will need to be updated to handle variable (item-level) data to encode 2D codes with real-time data such as a serial number, manufacturing date and / or batch / lot number.

It should be noted that 2D codes will not displace item-level RFID. RFID will still have its place due to the unique benefits of the technology as an AIDC data carrier. Look for products with both 2D codes and RFID in the future.

Ready to get started?

Want to dive deeper? Find out how other manufacturers in the automotive market are using custom QR Codes® to reduce errors, save money, and maximize productivity.

Click here to request a consultation.