How RFID On-Metal Tags Keep Your Inventory in Check

Does your company or institution have numerous assets such as laptops, servers, equipment racks, handheld computers, high-value tools, and other hardware? Is it difficult to keep track of these assets? Where are they? Who has which asset? Does an asset or asset class need to be serviced or replaced? Do assets mysteriously go missing?

TSC Printronix Auto ID RFID solutions can save you significant time and money in tracking and keeping an organized inventory of your company’s assets.

Why Manually Tracking Your Assets Doesn’t Check Out

For large companies and institutions, getting clear answers to these questions has traditionally been difficult, time-consuming, costly, and error-prone. Often, an entire team may need to devote overtime just to gather all of this data. This is an expensive practice, and usually not very popular with employees. Even with overtime projects to locate and identify assets, many assets often remain unaccounted for due to how detailed and manual the process is.

Another problem that organizations face when attempting to track assets with a barcode-based system is that assets will be accounted for at the beginning of the process then get lost later down the line. Although most large organizations have barcode systems in place to initially register or check out assets, when the time comes for users to find an asset to scan the barcode, the object’s location is unknown.

How Untracked Assets Put a Strain on Your Organization

A typical large enterprise, government entity, or school district can have thousands of laptops, projectors, servers, tools, and other high-value assets that need to be monitored. Such assets, whether stationary or portable, need to be accounted for.

In these particular environments, budgets can be limited and heavily regulated. For example, a typical school district can have up to a 3% annual decrease in budget. Taking preventive measures to invest in asset tracking and labeling technology will save your organization time and money because the cost of missing an asset can have serious negative impacts on your business processes. For example, a missing tool can completely stop an assembly process and be costly in terms of downtime spent trying to relocate the tool or in replacement costs for a lost tool.

How Highly Adaptive Asset RFID Tagging Works

By tagging assets with RFID tags, users can quickly locate and track assets with a significantly higher degree of accuracy than the process of manually scanning barcodes. Not to mention, it eliminates the need for late shifts and large amounts of labor needed to track down and document every tool and asset within a facility.

Once items are tagged, RFID readers at various locations can then identify every asset and tie the data into the company’s main software systems. Reading the tags can either be an automated process, occurring at pre-defined intervals, or on-demand. The RFID readers can be fixed at various locations and chokepoints, which allow an asset’s movement to be tracked. The on-demand option for asset tracking using RFID tags involves using handheld devices to locate and identify individual assets or the contents within an entire pallet of assets.

The tags used for such asset tracking processes usually also have printed information on their label. This is intentional, and the printed data serves as a backup record to the RFID processes. This is similar to how a barcode label’s user-readable portion serves as a backup to the barcode’s bars and spaces.

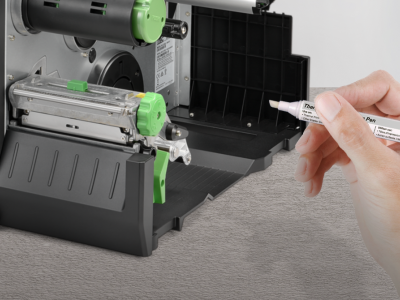

How the Award-Winning T6000e and T4000 Series RFID Printers Support Your Asset Tracking Needs

The T6000e and T4000 RFID series printers are part of our Printronix Auto ID enterprise lineup and are used extensively by service bureaus and other large entities for asset tracking applications. Service bureaus can pre-print and pre-encode the tags in large volumes, ship the tags to the user, and then the association between the tags and assets is done on-site by the user. Alternatively, the printing, encoding, and association can all be done together directly on-site by the user.

The T6000e and T4000 were designed from the ground up to work with a wide variety of RFID tags. Given that assets can vary in terms of size, construction, and physical form, different tag types are often needed for different asset classes. An on-metal tag might be the best solution for laptops, whereas a very small label might be needed for a handheld barcode scanner. Both the T6000e and T4000 RFID printers, give users the ability to work with a wide range of different tags. From a single printer without any complex changes to thick on-metal tags, very small tags, to plasticized Returnable Transport Item (RTI) tags, our RFID printers can handle them all.

“With the T6000e and T4000 enterprise RFID printers, users can easily swap out very different media types to print and encode labels used for asset tracking according to the needs of their business,” said Chris Brown, RFID Subject Matter Expert for TSC Printronix Auto ID.

Printronix Auto ID RFID-enabled printers have been tested and validated with many tags used in asset tracking, including on-metal tags, RTI tags, flag tags, and a variety of other tag constructions.

For listings of tags validated for use with Printronix Auto ID RFID-enabled printers, please refer to: Tested inlays and off-metal tags and Tested on-metal tags.

Printronix Auto ID RFID-enabled printers can handle both the wide variety and high volume of tags needed for asset tracking. Whether you run a service bureau and provide the tags to your customers, or you want to print and encode the tags in-house for your own asset tracking and identification, our RFID printers are up to the task.

To learn more about TSC Printronix Auto ID RFID printers and solutions, please contact your local sales representative.