Sustainable Label Production

If you want to sell to large companies, you will likely need to meet sustainability expectations.

Many companies are under pressure to commit to sustainable business practices. Businesses must comply with a variety of sustainability-related regulators. Additionally, consumers are increasingly considering sustainability in their purchasing decisions. For example, a Neilsen study determined that 66 percent of consumers are willing to pay more for sustainable brands. Companies can differentiate themselves by catering to these environmentally savvy customers.

SUSTAINABLE SUPPLY CHAIN

For many companies focused on achieving sustainability goals, the environmental impact of their supply chain can far outstrip that of their own operation. In these cases, there can be more opportunity for results through decisions made when purchasing goods and services than by acting only within their own business. For smart buyers, this means demanding more sustainable practices from their suppliers.

If you want to serve as a distributor for big brands, it can be valuable to source labels produced using the most current sustainable practices. Fortunately, Genuine Supply’s eco-friendly label production practices can help you meet the sustainability needs of your customers.

SUSTAINABLE LABEL PRODUCTION

DLS, Genuine Supplies' label manufacturing division, recognized the need to reduce our impact on the environment. We looked for an effective way to decrease our environmental impact, while streamlining our business practices… and we found it with power pellets.

The label industry has always created a large amount of waste during the label production process. Typically, this waste finds its way to landfills. But now DLS turns the label production waste in our Illinois facility into fuel pellets.

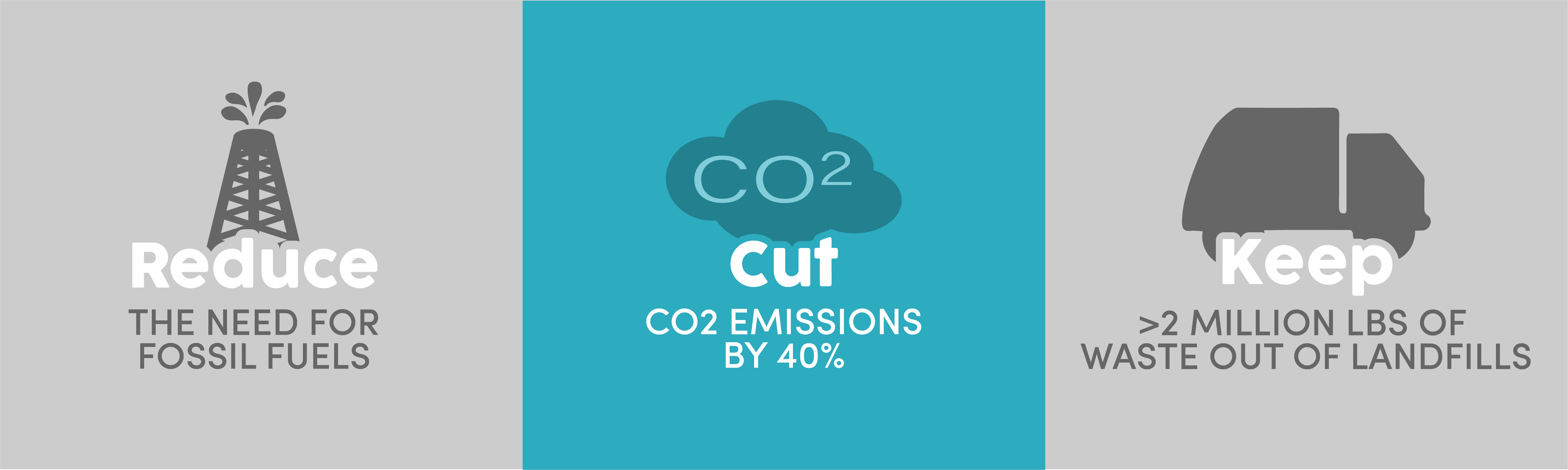

These power pellets are compressed label waste that can serve as a coal alternative for electricity generation. They not only reduce the need for fossil fuels, but also reduce CO2 emissions by 40% . And most significantly, each year we convert waste to power pellets results in over 2 million pounds of label waste that do not end up in landfills.

These results required everyone to participate and make significant changes to how our plant processes waste. Previously, all waste went to a compactor and was picked up and processed several times a week. Now, only label waste that will be turned into power pellets goes into a compactor specifically for power pellet production. Other recyclables like paper, metal, plastic, corrugated, packaging film and pallets are collected separately for recycling.

This sustainable method of waste disposal is not only attractive to buyers who are looking for environmentally friendly suppliers… it’s the right thing to do! In fact, in 2019 DLS was recognized with a special environmental award by TLMI; for our innovative waste solution.

Future plans include expanding this waste recycling program to our other facilities. We also continue to look for innovative sustainable label manufacturing practices. This aligns with our corporate values as well as our commitment to distributors.

We believe that sustainability efforts like these will help lessen our environmental footprint, while also helping you find greater opportunities with your sustainability conscious customers.